Your #1 tooling partner for the space coast

At Tri Tool, we design, develop and manufacture standard and custom tooling and machining solutions for the world's leading companies in aerospace, semiconductor, oil & gas, power generation and other industrial sectors. We are problem solvers. We leverage over 50 years of engineering expertise and an intense drive to solve our customers' challenges - to craft custom machining solutions which get them out of a jam and make their lives easier.

Whether searching for a standard machine, custom aerospace machining system, a modification to an existing tool, or the reconstruction of a discontinued part, Tri Tool is your partner in innovation. We can help you increase productivity, reduce downtime, and accelerate results.

CONNECT WITH YOUR SPACE COAST REP

TOOLS FOR EVERY CHALLENGE

Tri Tool designs and manufactures off-the-shelf pipe and tube tools for tackling your everyday machining challenges. Our flagship machine, the 300STS, has revolutionized small diameter tube and pipe facing and squaring across all industries, specifically aerospace.

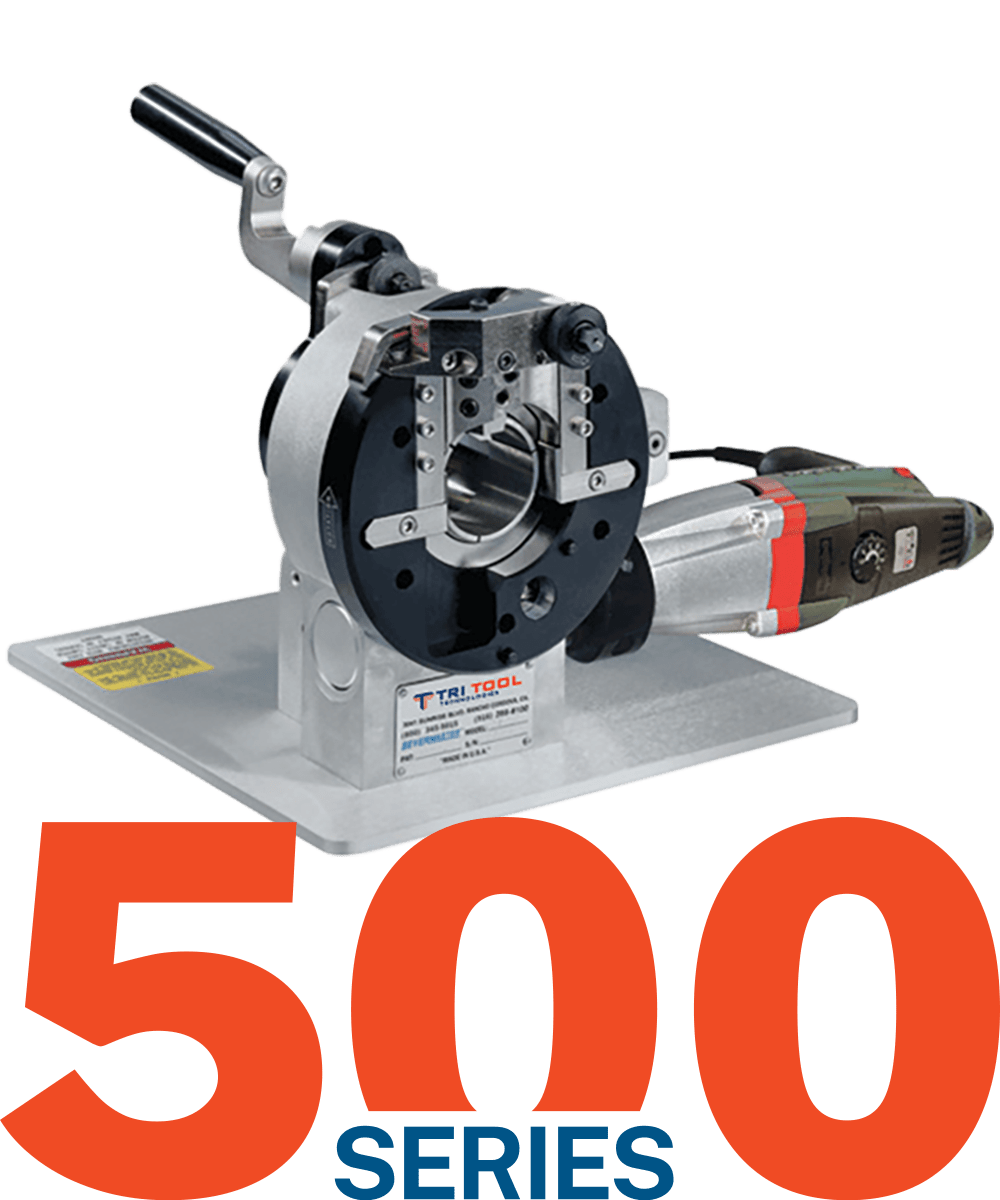

- Portable ID mount tube and pipe beveling, counterboring, facing equipment

- Deliver maximum precision and performance

- Provide perfectly square ends on cut lengths of tube and fittings

- Deliver rapid, repeatable results; easy set-up and operation

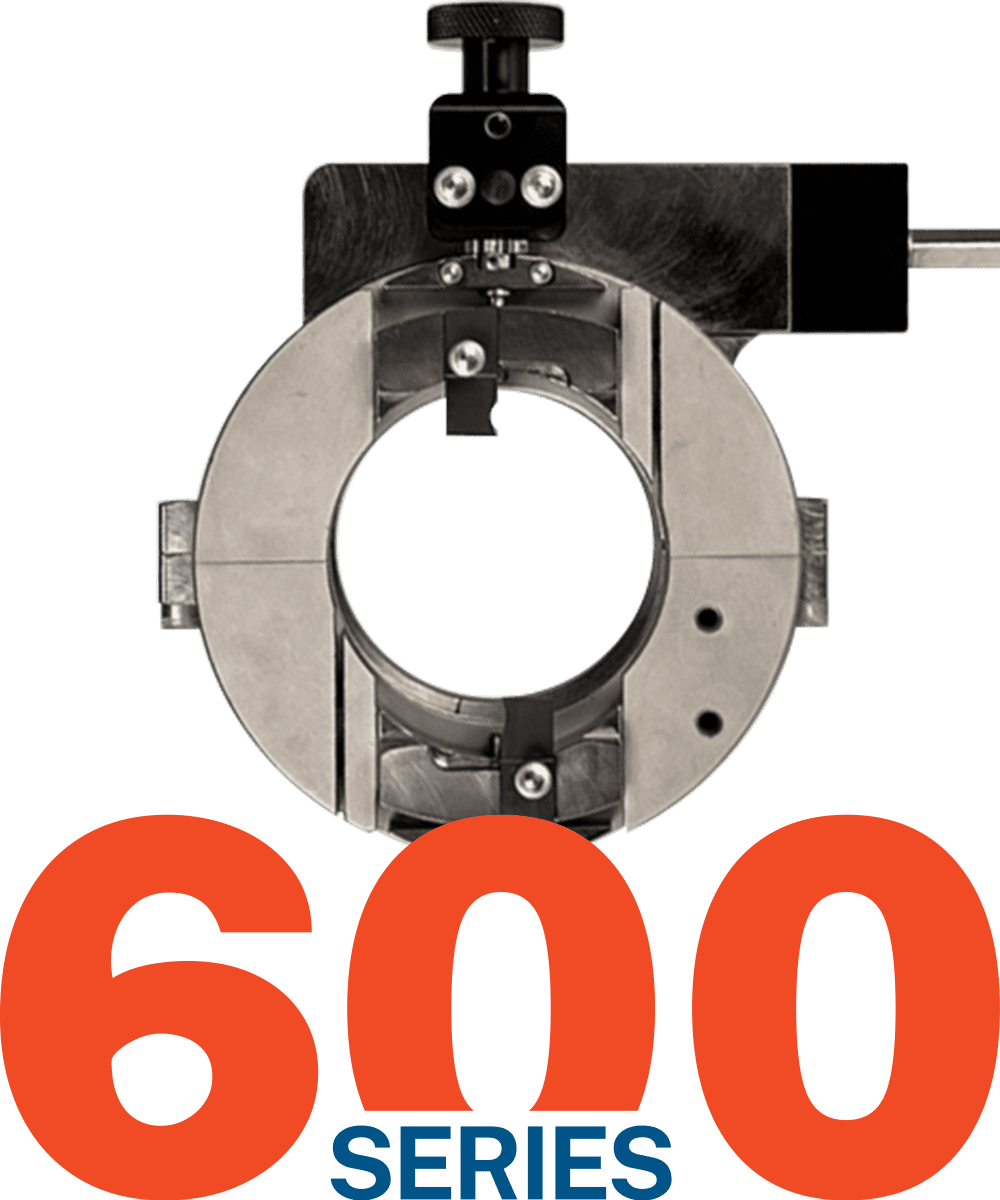

- Rapid set-up equipment for high-volume tube and pipe severing

- Boost productivity, produce weld-ready finishes, and minimize contamination

- Clamshells for all tube and pipe sizes, materials; in-line and end-prep versatility

- Best-in-class precision, maximum durability, easy set-up and operation

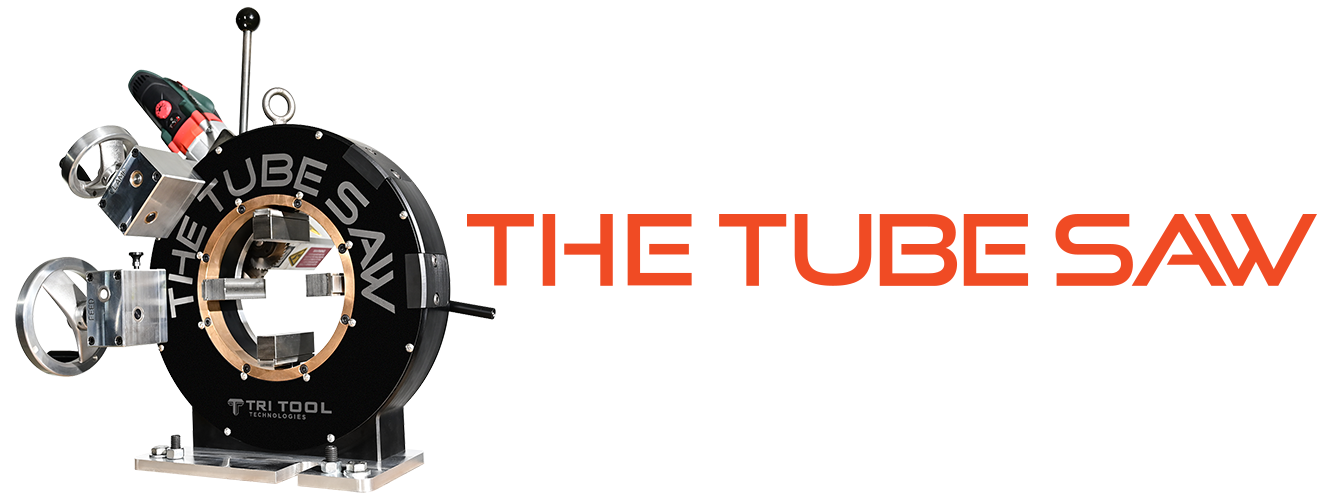

- Precision saw severs pipe and tube with a ready-to-weld finish, up to 6.625” (168.3mm) OD

- Ambidextrous design allows comfortable operation from left to right side of the machine

CUSTOM MACHINING

TRI TOOL ENGINEERS ARE READY TO SOLVE YOUR TOUGHEST CHALLENGES.

In-House Design Studios

• Complex machining and consulting• Processing equipment design

• Component and mechanism design

• Cutting tool design and manufacturing

State-of-the-Art Machining Complex

• Inspection and quality control departments• 5-axis and fully automated machining centers

• Large format VTLs

• Precision tool grinding

Field Machining Expertise

• Hundreds of complex jobs completed• High fidelity / high risk machining applications

• Field-proven custom machining solutions

In a jam? If you need reliable on-site machining help, contact Tri Tool today. Our team of field machining experts are equipped to handle the most demanding challenges to help you safely and efficiently reduce downtime and maximize productivity.

Aerospace Case Study

Leading manufacturer of reusable rockets uses custom precision micro-boring system from Tri Tool for difficult-to-reach weld root penetration

One of the world's most innovative private aerospace manufacturers, was fabricating a two-part small diffuser nozzle weldment at their Hawthorne facility when engineers noticed a small but significant problem. The arc welding process they were using had left a weld root penetration inside the nozzle chamber. If not removed, the weld root penetration would disrupt the flow of fluid and compromise the nozzle's performance.

Discover how the private aerospace company avoided redoing its entire fabrication process by working with Tri Tool to design and develop a custom tube squaring machine to remove the difficult-to-reach weld root penetration.