Around the corner. Around the globe.

For on-site services done right, faster, the first time, Tri Tool Field Machining Services has you covered.

2,000+

Projects

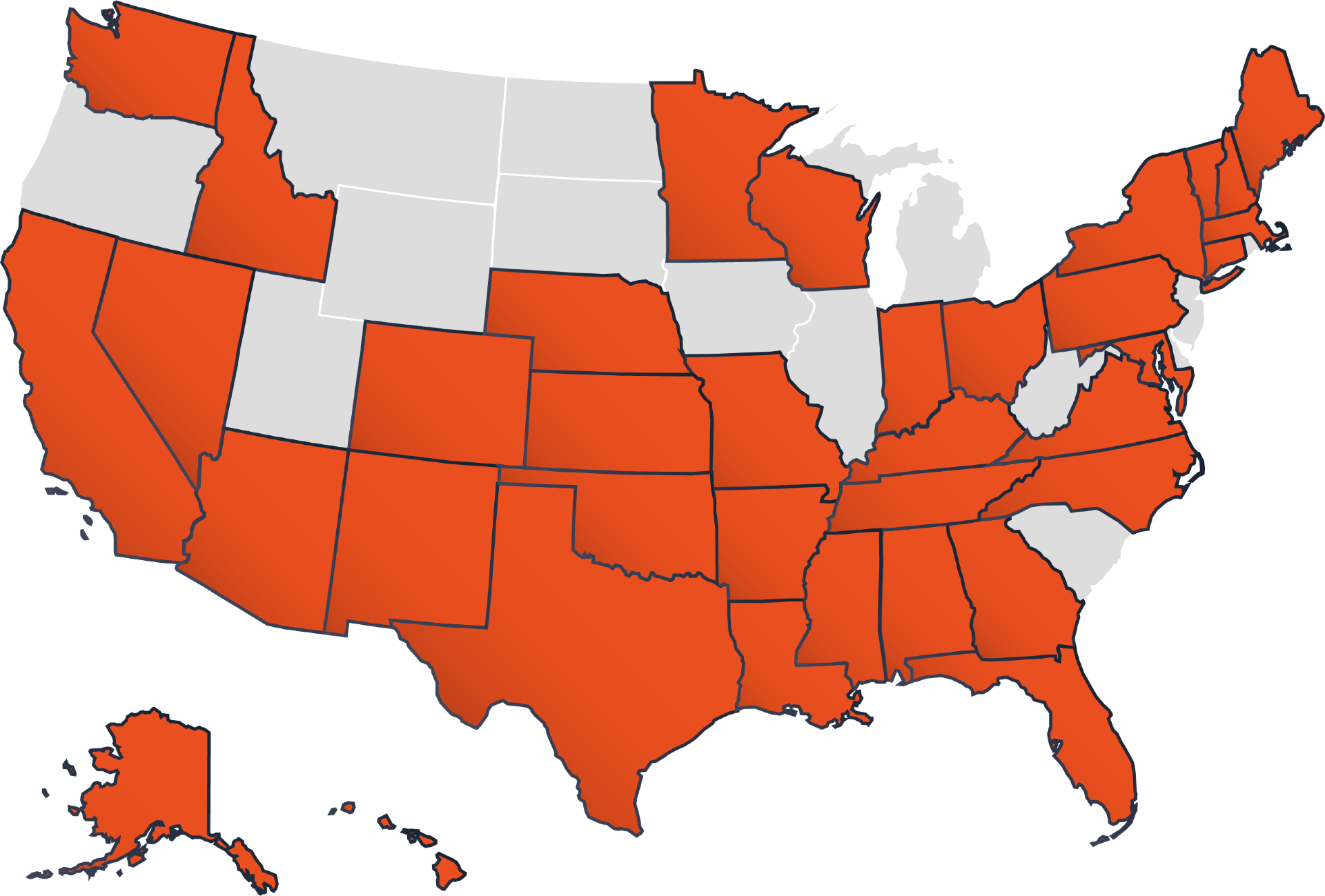

34

States

16+

Countries

International Project Locations

- United Arab Emirates

- British Columbia

- Republic of Korea

- Norway

- Belgium

- Italy

- United Kingdom

- China

- Egypt

- Sweden

- Russia

- South Korea

- Bolivia

- Brazil

- Dubai

- Finland

- Offshore areas of the Gulf of Mexico, Nigeria and Angola

NATIONAL & INTERNATIONAL CUSTOMERS:

There when you need us.

When equipment fails, you need an immediate solution. When project timelines are accelerated, you need more manpower. When the right equipment doesn’t exist, you need a bespoke tool made to order.

Whatever the challenge, you can rely on Tri Tool Field Machining Services. We are pioneers of in-situ machining. For more than 50 years, we have worked alongside companies in the most demanding industries, providing a wide variety of services including industrial infrastructure, maintenance programs, equipment installations, emergency repairs and modifications, and new construction.

Our experienced, highly skilled on-site services team respond quickly—mobilizing within 24 hours when necessary—to help you reduce downtime, lower costs, and keep your critical equipment in top condition. As an OEM, we have the most comprehensive range of portable machine tools ready to go; but if we don’t have the right tool, we will quickly modify an existing one or custom engineer a bespoke tool for your specific project.

Wherever and whenever you need us, Tri Tool Field Services will show up ready to work at a productivity rate that exceeds your expectations and with a quality unsurpassed in the industry. We execute with precision and deliver ahead of schedule.

Tri Tool Field Machining Service team supports:

- Power Generation

- Oil & Gas

- Nuclear Decommissioning

- City Municipals

- Pulp and Paper

- Military and Government Contractors

- Refining, Petro Chemical, Chemical Plants

Field Services Capabilities

Pipe Severing - Utilizing cutting-edge equipment and innovative machining processes, our Field Services team can sever all types of materials, including plastics, steel, stainless steel, Inconel, titanium, and many other alloys and exotic materials, with absolute precision and squareness. Our equipment line covers a wide range of pipe sizes from 1” to 60, but as an Original Equipment Manufacturer, we have custom engineered solutions to sever 120” pipes for specific applications.

Pipe Beveling – At Tri Tool, we specialize in portable ID and OD pipe beveling machines, and our Field Services team can apply any type of bevel to any degree required for your workpiece positioning system. Our industry-leading pipe beveling tools are specifically designed to operate with low radial and axial clearances, delivering maximum performance and accuracy on pipe sizes from 1” to 60”.

As an Original Equipment Manufacturer, we have ready access to a wide range of portable machines and can quickly develop custom engineered solutions to meet your precise project requirements. With decades of experience and know-how, our field machinists are experts in on-site turbine machining, providing the following services:

- Machining on rotational energy items, such as the turbine, bearings, housings, and components of the turbine.

- Machining on the valves, flanges, joints, steam chest, and other components controlling the kinetic energy source of the turbine.

- Machining on the piping, motors, tubes, vessels, and other components supporting plant operations.

- Removing and replacing major system components, such as a steam generator, heater change-outs, tube bundle replacements, and performing extended power upgrades, such as turbine and generator upgrades and valve work.

Safety is optimized in this system with incoming and outgoing mechanized pipe handling racks that require no manual pipe handling. Cycle times are optimized with laser-assisted pipe end alignment and rapid machining by dual, seven axis CNC machines equipped with real-time monitoring and the latest safety features. Our Field Services team is trained on manual and CNC equipment to provide you with the most effective solution for your specific project.

VIDEO: How Tri Tool Field Machining Services helped the Sauer Group develop a new welding process and stay on schedule

While constructing a new cryogenic gas processing plant in Noble County, Ohio, the Sauer Group relied on Tri Tool Field Services to assist with the on-site welding. Tri Tool developed a new welding procedure specific to this project that enabled welds to be completed in a third of the time, helping the Sauer Group cut costs and stay on schedule.

Field Services Case Study

Faced with an emergent need to replace a reactor coolant system primary check valve at the Sequoyah Nuclear Plant, the Tennessee Valley Authority turns to Tri Tool to deliver quality on an expedited time frame.

During a routine outage at the Sequoyah Nuclear Plant a nuclear power plant owned by the Tennessee Valley Authority (TVA) that generates enough power for 1.3 million homes each day plant personnel unexpectedly found that a Reactor Coolant System (RCS) primary check valve needed to be replaced. However, the valve was located in a very congested area that required special considerations due to various radiological conditions.

Find out how Tri Tool mobilized a crew of pipefitters, machinists, and welders within 24 hours to execute a "like-for-like" replacement of the valve with zero safety or performance issues.

Field Services News

Top 5 ways the oil and gas sector can cut time, labor and costs in pipeline maintenance and construction

The future of oil and gas is now. With the sector playing a fundamental role in the global transition to clean energy, oil and gas companies must adopt new pipeline equipment and operational strategies that can fuel higher performance.

Orano USA partners with Tri Tool to develop a custom engineered solution to remotely sever underwater jet pump diffusers in Vermont Yankee nuclear reactor vessel

In 2014, the Vermont Yankee Nuclear Power Station permanently shut down. Orano USA, a leading technology and services provider for decommissioning nuclear energy facilities, was tasked in Phase 1 of the decommissioning project to depose a portion of the nuclear reactor pressure vessel and remove...

FlexJoint™ Replacement on Shell's Bonga Floating Production, Storage, and Offloading Vessel Serviced by Tri Tool

Floating production is the system of choice for all deep-water developments off West Africa to date. The absence of pipelines, the extent of the giant reservoirs and the mild metocean conditions all favor use of spread-moored floating production, storage, and offloading (FPSO) vessels.